Quality & Continual Improvement

“Every system is perfectly designed to get the result that it does.”

~Dr. W. Edwards Deming

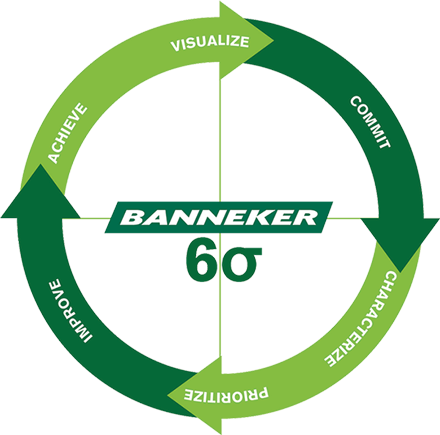

The Banneker Operating Standards System (B.O.S.S.) serves as our Quality Management System (QMS) which has been established on our ISO/AS certifications and supplemented by a leading edge Lean Six Sigma Program and a dynamic Company culture of continual improvement.

Audit Ready

As a quality-driven organization, we have the processes and systems in place that allow an auditor to scope and perform an audit over our entire business system and provide actionable feedback.

Socioeconomic Value-Add:

- Certified Small Business (U.S. SBA)

- Certified Disadvantaged Business Enterprise (DBE)

- Certified Minority Business Enterprise (NMSDC)

Certifications

- ISO 9001:2015 & AS9100 Rev. D

- AIB Food Certification

- FDA Food Storage License

- Previously ISO 14001 certified

- Previously DLA Qualified Suppliers List for Distributors certified for Fasteners & Pins

Environmental Quality Policy

Banneker recognizes and accepts its responsibility to be a good steward of the environment and to help achieve a state of sustainable development. In support of these responsibilities, we have established the following commitments:

• Compliance to all applicable state, federal, and local legal requirements with a goal of ‘beyond compliance’ wherever practical and possible.

• Prevention of pollution in all its forms.

• Conservation of natural resources, including energy, through source reduction, reuse and recycling wherever practical.

• Continual environmental performance improvement through the involvement of all Team Members and partnership with the local community.

Lean Six Sigma Training

The second component of Banneker’s IBQMS program is one of the most critical steps of our Quality Management System. Our robust Lean Six Sigma program involves six to eight months of rigorous classroom education supplemented with practical application of the processes involved and tools used. A Six Sigma project, results in cost reduction, efficiency gains and/or profit increase, serves as the graduating culmination of the training program and creates a special infrastructure of Six Sigma “Green Belts” within the Company.

This training also includes “7S Training” – a workplace organization method that focuses to organize and maintain work space areas for efficiency and effectiveness. Traditionally a 5S Program (Sort, Straighten, Shine, Standardize and Sustain), Banneker Supply Chain Solutions has added Safety and Security to our program to address the ever increasing needs of our customers.